Client Requirements

The client, a prominent beverage manufacturer in the United States, aims to implement automation in their beverage can production line. They were experiencing challenges related to defective can labels, where the brand labels or logos were incorrectly printed.

To address this issue, the client wants to identify and reject cans with flaws in label printing. The client requires a computer vision-based solution, and they plan to install a camera setup along their existing conveyor line, which will provide a real-time stream (rtsp) of the cans as they move along the conveyor belt. The system's response time should be less than 0.05 seconds, and the desired accuracy level should be set at a minimum of 90%.

Thinkitive Solution

Thinkitive Technologies has assembled a team of computer vision experts and data scientists to address the client's requirements. They developed an object detection model trained on a dataset comprising over 20,000 images of defective and good beverage cans. The model was specifically trained to identify various flaws in can labels, including missing or incomplete logos, incorrect product names, and excess paint.

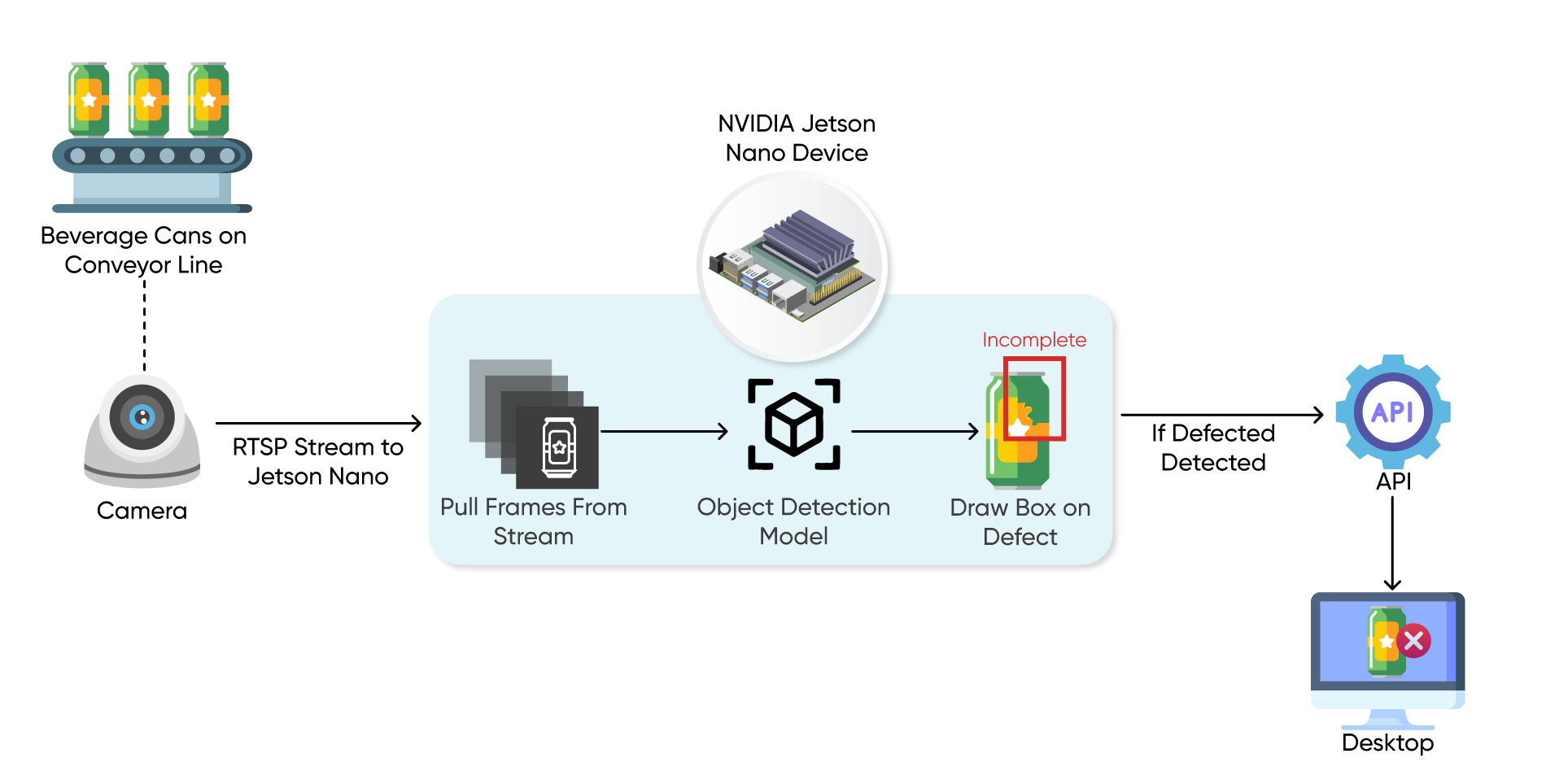

An NVIDIA Jetson-nano device, an edge computing device designed for AI and deep learning applications, will be installed alongside the camera setup to deploy the model. Jetson devices provide high-performance computing capabilities for running AI algorithms locally at the edge, ensuring low latency and reducing dependence on cloud servers. Considering the nonscalable constraint of edge devices, the deployed model was optimized for lightweight operation while maintaining a balance of accuracy and low latency.

In the implementation, the RTSP stream from the camera is directly connected to the Jetson Nano device. Whenever a defect is detected in a can, the system will activate an API that provides details of the defective can. These details can be displayed on a user interface (UI) for further analysis or action.

Solution Highlights

-

The object detection model developed by Thinkitive Technologies for the client's beverage can production line achieved high accuracy and low latency. The model was optimized to be lightweight while balancing accuracy and performance.

-

To ensure the model's effectiveness, extensive testing, and validation were conducted. The model achieved a Mean Average Precision (MAP) of 85% for detecting minor defects and 98% for detecting significant defects. This indicates a solid ability to identify flaws in can labels accurately.

-

The system's response time was successfully achieved within the client's requirement of less than 0.05 seconds. This rapid response time allows for real-time defect detection and rejection without causing significant delays in the production line.

-

The direct connection of the camera's RTSP stream to the NVIDIA Jetson Nano device facilitated seamless integration and efficient processing of the video feed. This setup ensures that the defect detection and rejection process occurs in real-time, providing immediate feedback to the production line.

-

The activation of an API upon defect detection allows for the automatic generation and retrieval of detailed information about the defective cans. This information can be easily accessed and displayed on a user interface (UI) for further analysis, facilitating effective decision-making and corrective actions.

-

The use of the NVIDIA Jetson Nano device enabled edge computing, minimizing the reliance on cloud servers and ensuring faster processing and decision-making at the production line itself. This localized approach reduces latency and provides a more efficient and responsive defect detection system.

-

The overall solution provided by Thinkitive Technologies successfully addressed the client's requirement for automated defect detection and rejection in their beverage can production line. Combining a carefully trained object detection model optimized for the Jetson Nano device and seamless integration with the camera's RTSP stream resulted in an accurate, low-latency system that improved the quality control process.

Value Delivered

-

Enhanced Product Quality: By implementing the computer vision-based solution, the client experienced improved product quality. Defective cans with flawed label printing were accurately detected and rejected in real time, preventing them from reaching the market. This resulted in higher overall product quality and reduced customer complaints.

-

Increased Efficiency: The automated defect detection system on the production line significantly increased operational efficiency. Manual inspection processes that were time-consuming and prone to human error were replaced with a fast and reliable computer vision solution. The system's less than 0.05 seconds response time ensured minimal impact on the production speed.

-

Cost Savings: By automating the defect detection process, the client achieved cost savings by reducing the need for manual labor and the associated expenses. The system's accuracy level of over 90% ensured that only defective cans were rejected, minimizing waste and optimizing resource utilization.

-

Real-Time Insights: The NVIDIA Jetson Nano device integration enabled real-time analysis and insights. The activated API provided detailed information about the defective cans, which could be displayed on a user interface (UI) for immediate analysis and further actions. This facilitated quick decision-making and proactive quality control measures.

-

Edge Computing Advantages: Leveraging the NVIDIA Jetson Nanodevice for edge computing offered several advantages. The localized processing reduced dependence on cloud servers, ensuring faster processing and decision-making directly at the production line. This minimized latency and provided a more efficient defect detection system.

Technologies and tools

-

Object Detection, NVIDIA Jetson, Edge Device, RTSP stream

-

Python, PyTorch, Tensorflow, ONNX, OpenCV, Google Colab